Vehicle Tray Table

Project Overview

This project was born out of a need for a functional and portable workspace that could be easily set up in various vehicles. I designed and built this project during COVID when I had a remote schedule allowing me to have travel flexibility, meaning I was frequently on the go and in the car but still having work to do. I created an innovative (definitely not regulation) device to provide a stable surface for doing work, eating, or other activities while on the go. The table is designed to be adjustable and compact allowing it to fold and integrate into the vehicle when not in use. The project provided me with hands-on experience in Fusion360 CAD, CAM, and a better understanding of applied loads, material selection, and rapid prototyping. I received the Fenn Brothers Innovation Award from my school for my work.

Finished Tray Table in Vehicle

Folded Tray Table in Vehicle

Key Design Choices

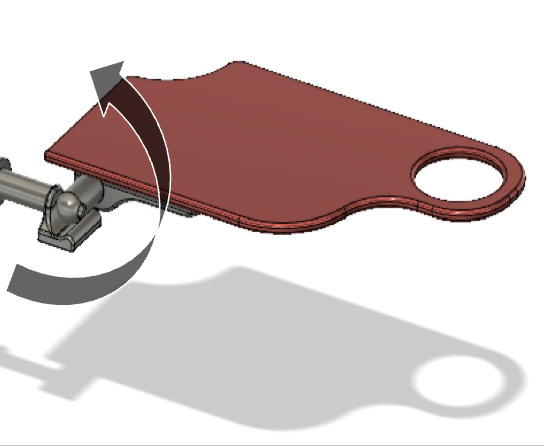

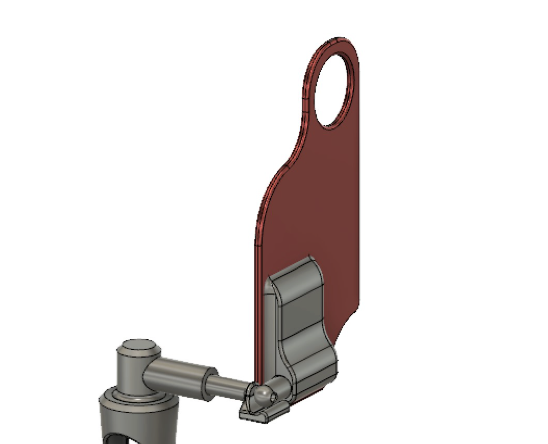

The storage stow-away mechanism for this project was truly the focal point as I adopted the pivoting desk design of lecture hall seating. Developing the two different restricted axes of rotation took much consideration and required meticulous design for manufacturability. I utlilized mortise and tenon jointery to lock the components together after nesting the rotational component in the interior of the two. For the desktop itself, I wanted it to feature a cupholder since the system attaches to the vehicle by way of the cupholder, but this feature proved inefficient and unfeasible in the current orientation due to the significant weight.

Before First Rotation

After First Rotation

Before Second Rotation

After Second Rotation

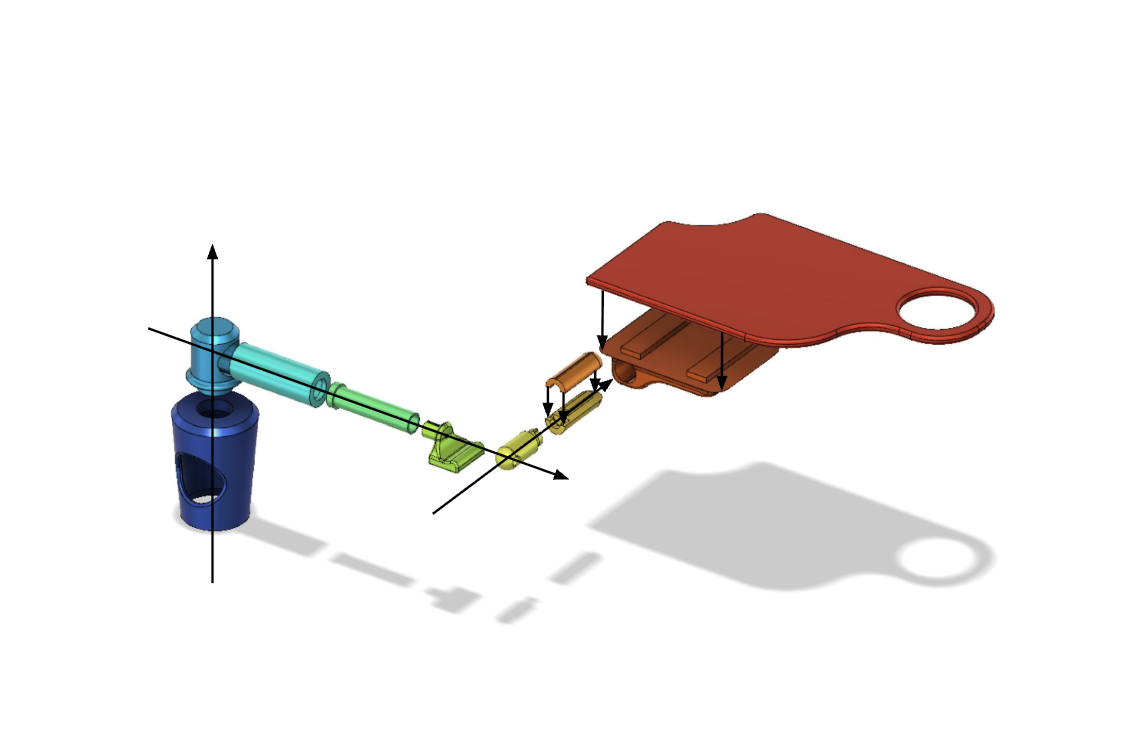

Assembly of Tray Table Components

Iterations and Improvements

This project involved tons of iteration, as my V1 cupholder component didn't quite fit snugly into the cupholder and the arm didn't quite align with the edge of the seat, meaning I had to redesign the entire, yes, entire, part various times. Throughout my iterations, multi-day 3D prints, and much wasted filament, I learned to break down the larger component into the parts that This project involved tons of iteration, as my V1 cupholder component didn't quite fit snugly into the cupholder and the arm didn't quite align with the edge of the seat, meaning I had to redesign the entire, yes, entire, part various times. Throughout my iterations, multi-day 3D prints, and much wasted filament, I learned to break down the larger component into the variable parts, reducing waste, and fine-tuning the individual components without needing to redundantly print the whole part. I also implemented a telescoping arm in the V3 design to allow for more vehicle adaptability.

V1 Component Iteration

V2 Component Iteration

V3 Component Iteration

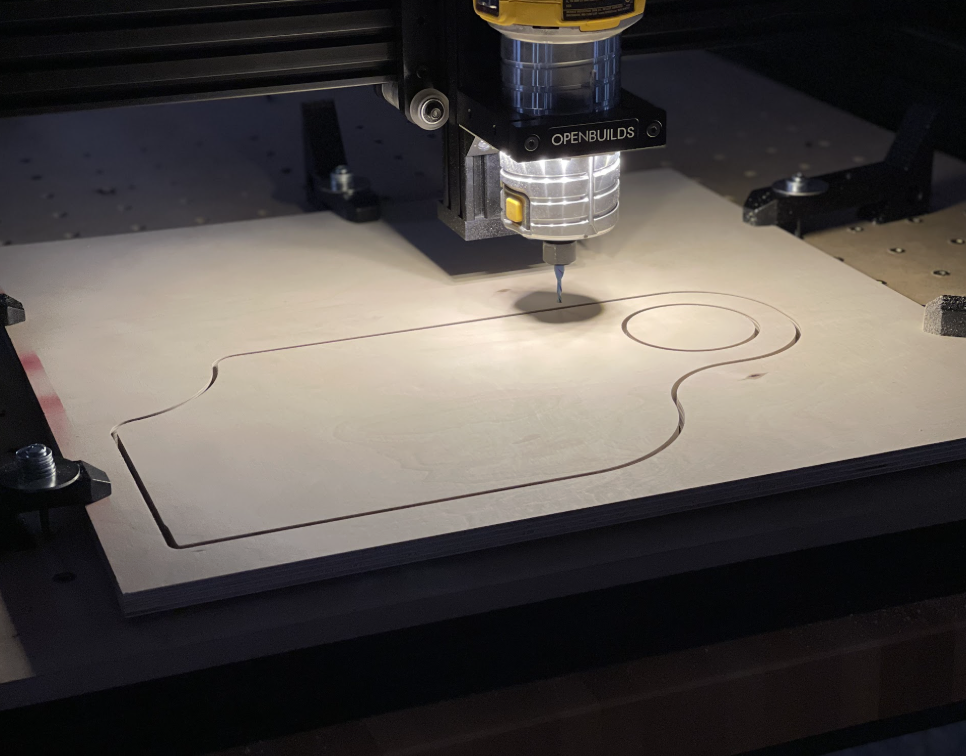

CNC Machine

This project allowed me the unique opportunity to not only learn how to use Fusion360 CAM software but also build a CNC machine (Openbuilds Lead 1010) and be the first to use it, which was a very gratifying experience to see it all come together.

Assembly of Tray Table Components

Project Limitations and Critiques

While this project was successful in many aspects, there are areas for improvement. The stability of the table could be enhanced with additional support mechanisms, especially considering the large moment created when weight is applied to the edge of the table. Additionally, while the materials used were sufficient for the initial design, exploring lighter yet stronger materials could improve portability without compromising strength. Further modularity would also need to be developed so the cup holder attachment could be adjusted to fit different cup holder sizes. Besides improvements on the design itself, key regulations towards automobile safety must be considered, as, the way the table currently functions, it would not be safe or legal to use while the vehicle is in motion due to it both blocking the airbag mechanism and creating a potential projectile object in the case of a crash.