Gantry Workflow Redesign

Project Overview

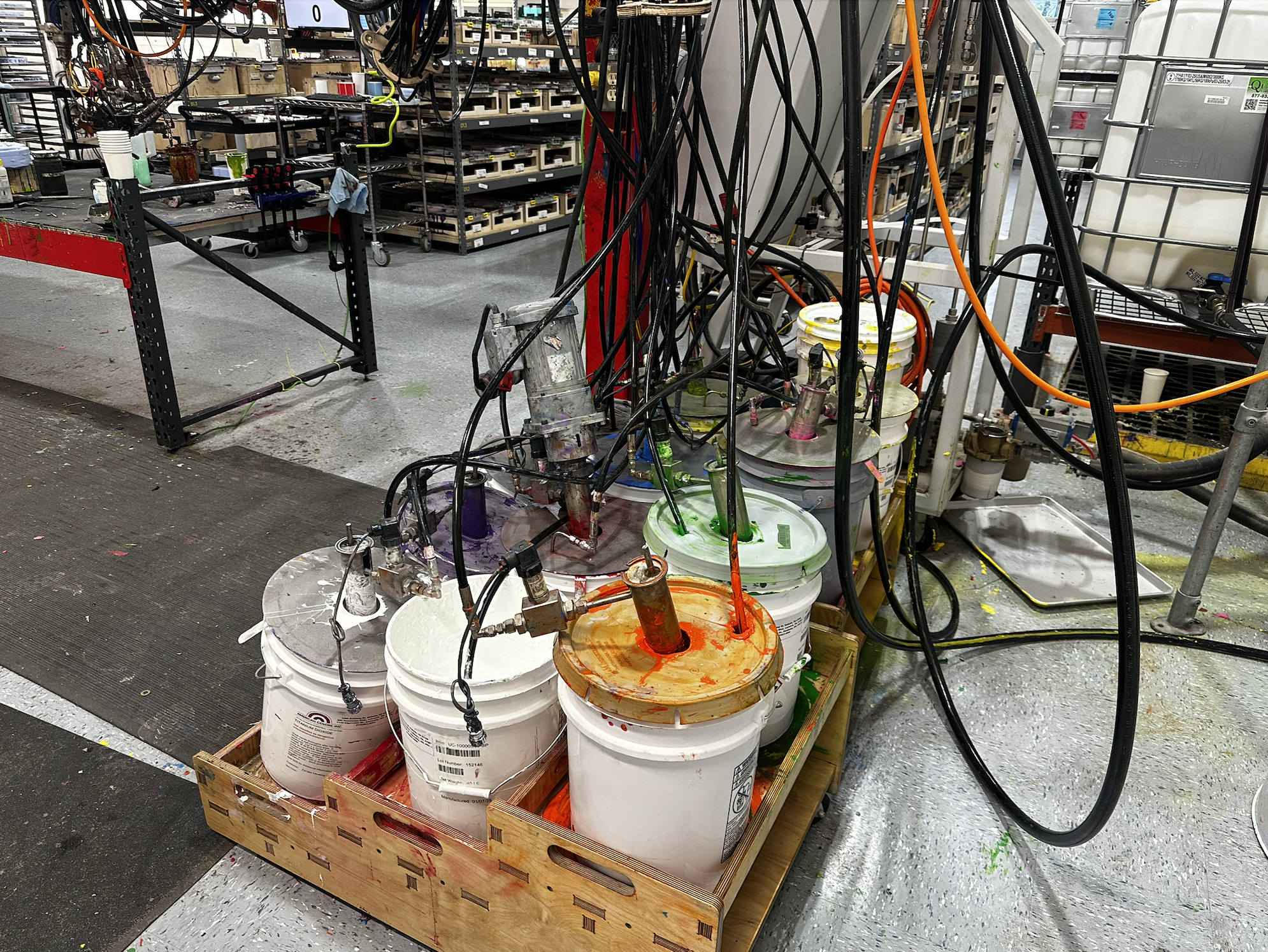

Overarching internship project to redesign an obscelete gantry workflow system for a midsize manufacturing company that had outgrown their prior manufacturing plant but maintained the same gantry setup. The main objective of the project was to design a new system that would eliminate mess, reduce wasted material, and improve overall efficiency of the operational workflow.

New Gantry Workflow System

Old Gantry Workflow System

Workflow Improvements

The redesigned gantry workflow system incorporates several key improvements that collectively enhance the efficiency and usability of the system including:

- Improved trace of hose issues with color coded direction indicators on each hose

- Efficient out-of-the-way storage of extra material

- Organized bucket layout for improved foot-traffic flow

- More compact design that reduces the overall footprint of material storage

- Innovative design that features 3D printed components for concealing material within buckets

- Hose fitting connectivity that allows for efficient line transfers with minimal cleanup

New Bucket and Storage Layout

Messy Buckets in Old System

Concealed Buckets in New System

Design Choices

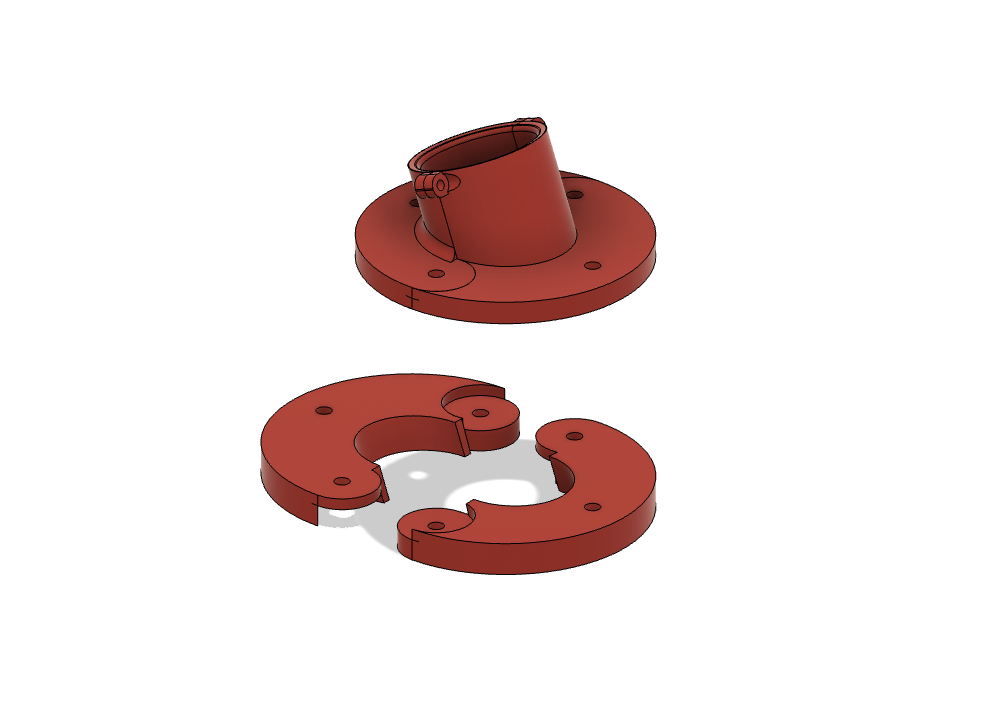

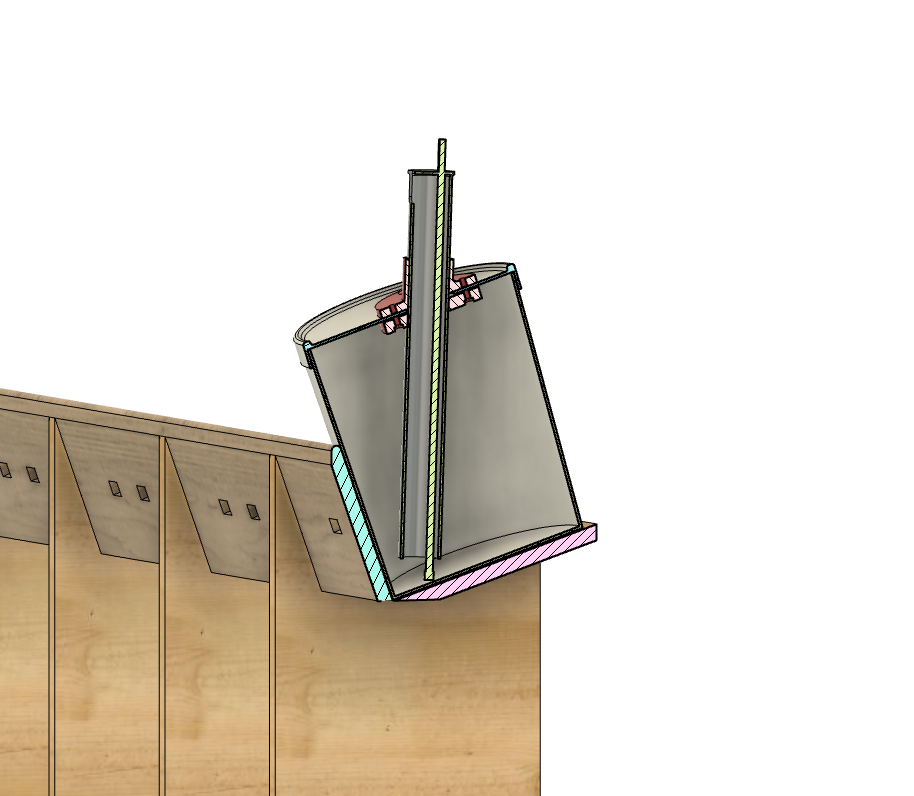

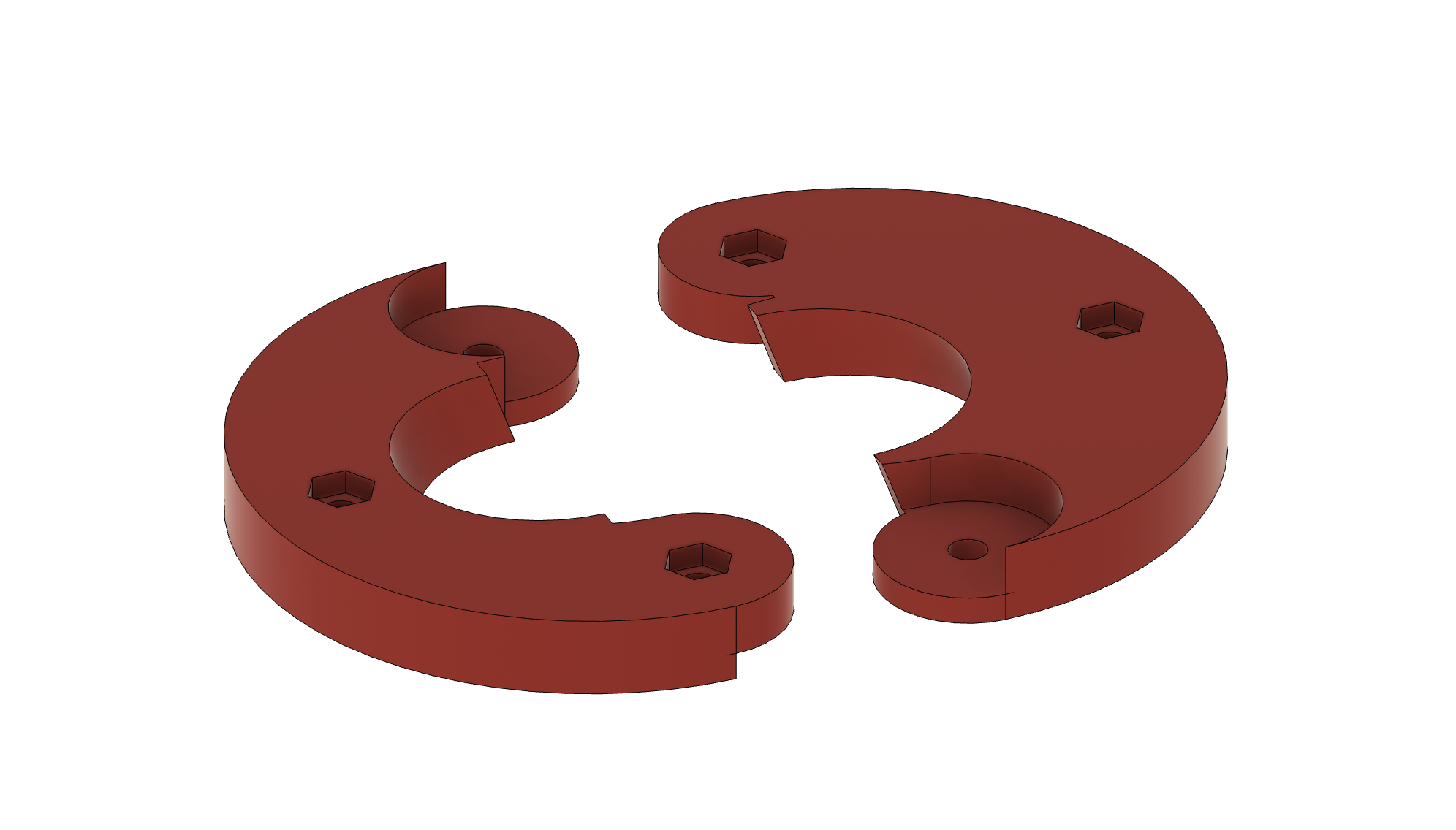

Key design choices involved developing a collar mechanism that could create a closed system between the pump and the material in the buckets. This prototyping phase involved meticulous attention to detail and putting intention behind each decision I made, such as creating hex shaped indents in the bottom of the 3D printed parts so the installation process would go quicker not needing to use a wrench on the backside. Additionally, I had to consider how the colllar, pump, and bucket would integrate together, so I designed the components to have a 20 degree tilt so the pump would sit in the bottom-most part of the bucket to allow it to collect maximum material. Another key design choice was integrating bulkheads into the trollies on the gantry to allow the thicker, 1/2" hoses, to encounter less wear-and-tear in comparison to the prior system due to their larger bending radius.

Model of Collar Attachment in Fusion360

Cross-Sectional View of Pump in Bucket

Hex Cutout on Underside of Component

Bulkheads Attached to Trollies on Gantry for 1/2" Hoses